What you need to know about FDA 21 CFR Part 210

FDA 21 CFR 210 is one of the handful of key regulations which US pharmaceutical and contract manufacturing companies will encounter.

21 CFR 210 compliance is a crucial facet of current good manufacturing practice, or cGMP. Crack 21 CFR 210 and its definitions of key cGMP elements, and your organization is well on its way to a compliant and robust drug manufacturing system.

Here's everything you need to know about the standard and how to comply.

Table of Contents

What is 21 CFR Part 210?

FDA 21 CFR 210 is a regulatory standard outlining the minimum requirements for how pharmaceutical drugs used in the United States are manufactured, processed, packed and held.

It forms part of the FDA's current good manufacturing practice (cGMP) expectations: a subset of GxP designed to guarantee the purity, potency, identity, quality and safety of drugs going into patients' bodies by controlling the way such drugs are produced.

Why is 21 CFR Part 210 important?

21 CFR 210 is an important standard for two reasons.

Firstly, it's mandatory for pharmaceutical manufacturers looking to market their drugs in the United States. Unlike optional pharma standards like ICH Q10, Part 210 compliance - and by extension, demonstrable cGMP - is a bare-minimum must-have requirement for drugmakers.

Let your 21 CFR 210 compliance slip, and your organization is at serious risk of fines, lost business, reputational damage and even complete shutdown. Your product becomes officially 'adulterated' and a crippling recall will ensue.

Secondly, we should consider why 21 CFR 210 and cGMP requirements were introduced in the first place.

The FDA was instructed by the US Congress in 1962 to enshrine cGMP as a baseline requirement after a string of dangerous drugs, like sulfathiazole and thalidomide, made their way to market and wreaked havoc, injury and death on thousands of Americans.

Part 210 is therefore a crucial protective shield helping to ensure the safety and efficacy of pharmaceutical product - and the health and wellbeing of patients using it.

Considering outsourcing your manufacturing?

Difference between 21 CFR Part 210 and 211

21 CFR Part 210 guidelines for pharmaceuticals are often tackled as one half of a pair, alongside CFR Part 211. Although complementary, they are different.

Where Part 210 covers manufacturing, facilities and controls, Part 211 covers additional areas for finished drug products, such as labeling, production processes, equipment management and personnel.

It's for this reason you'll often see both parts grouped together as a single quality objective: '21 CFR Part 210/211 compliance'. For the purposes of pharmaceutical and contract manufacturers, it makes little sense to tackle one without the other.

Part 210 has a broader scope than Part 211, referring to 'all drugs' rather than just 'finished' products.

It's also primarily a definitive standard, mapping out and defining key cGMP terms rather than prescribing specific processes. It therefore connects not only with Part 211, but other cGMP standards like Part 225 (medicated feeds) and other non-pharma cGMP benchmarks like Part 1271 (tissue-based products), Part 600 (biologic) and Part 606 (blood).

Part 211 and its subparts, meanwhile, go deeper into specific actionable areas like building management and labeling control and, for that reason, Part 211 is seen more as the 'meat' of cGMP for pharma businesses.

Broadly speaking, 21 CFR 210 outlines the 'what' while 21 CFR 211 covers the 'how'.

Embed repeatable 21 CFR Part 210/211 compliance, and your pharmaceutical organization is effectively meeting the demands of cGMP.

RELATED READING:

21 CFR Part 210 guidance and requirements

With that in mind, let's look closer at exactly what 21 CFR 210 requires.

Part 210 is divided into three sections: status of cGMP requirements, applicability of cGMP requirements, and definitions of key pharmaceutical terms to remove ambiguity.

Scope and applicability of 21 CFR Part 210

The scope and applicability of 21 CFR 210 is laid out in the first two sections of the standard.

§210.1, "Status of current good manufacturing practice regulations", maps out what exactly cGMP demands.

Organizations working towards Part 210, 211, 225 and 226 must meet the minimum requirements to:

"... assure that such drug meets the requirements of the act as to safety, and has the identity and strength and meets the quality and purity characteristics that it purports or is represented to possess."

Failure to do so, as we touched on above, is to render your drug officially 'adulterated'.

The scope of 21 CFR 210 is then mapped out further: as well as pharma businesses, non-pharma biologic organizations working with the 'recovery, donor screening, testing... processing, storage, labeling, packaging, or distribution of human cells, tissues, and cellular and tissue-based products (HCT/Ps)' must meet Part 210 as well as Part 1271.

§210.2, "Applicability of current good manufacturing practice regulations", then spells out another important point about the applicability of 21 CFR 210. The cGMP requirements:

"... shall be considered to supplement, not supersede, each other... in the event of a conflict between applicable regulations in this part and in other parts of this chapter, the regulation specifically applicable to the drug product in question shall supersede the more general."

21 CFR 210 also makes clear that investigational products for Phase 1 studies are exempt from 21 CFR 211 compliance until they enter Phases 2 and 3.

Quality management system requirements

As we've explored above, 21 CFR 210 is descriptive and definitive rather than prescriptive.

The remainder of the standard pertains to definitions of key cGMP ingredients and requirements.

There are therefore few explicit mentions to quality management system (QMS) needs, even though a robust QMS is obviously crucial for any GxP compliance.

21 CFR 210 does however define the 'quality control unit' as a key cGMP requirement:

Quality control unit means any person or organizational element designated by the firm to be responsible for the duties relating to quality control.

Complying with 21 CFR Part 210

21 CFR 210 compliance really hinges on grasping the definitions mapped out in the standard, then ensuring the more detailed requirements of Part 211 correspond to them.

This should include ensuring that your quality, training and facility management all align with Part 210-defined requirements.

FURTHER READING: How to master pharmaceutical QA in 4 steps

Establishing and maintaining a compliant quality system

As above, your organization should include a dedicated quality control unit responsible for checking and guaranteeing the quality and integrity of both:

- Your manufacturing processes

- The drugs themselves that come from those processes

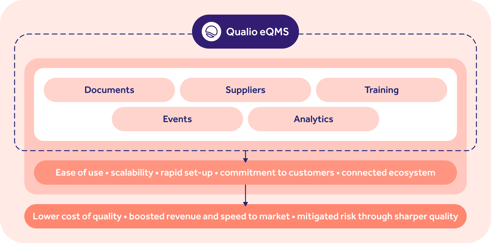

For an idea of the primary elements that should feed into your pharmaceutical quality system, check out how we structure our electronic quality management system (eQMS) software:

Document, supplier, training and quality event management, underpinned by robust reporting and analytics, are the key areas you should consider as you look to build a 21 CFR 210-compliant QMS.

And 21 CFR 210 also offers a crucial definition of acceptance criteria:

... the product specifications and acceptance/rejection criteria, such as acceptable quality level and unacceptable quality level, with an associated sampling plan, that are necessary for making a decision to accept or reject a lot or batch.

Your QMS should be built with this acceptance criteria in mind, so that drug quality parameters can be continuously checked and enforced.

FURTHER READING: QMS in pharma: 3 safeguards to ensure compliance

Implementing effective personnel training and qualification programs

Does everyone in your business understand what a 'batch' is?

What about theoretical vs. actual yield?

Nonfiber releasing filter?

How will your representative samples be collected and interrogated to ensure drug quality?

Answering these questions is vital for passing a 21 CFR 210 cGMP inspection - and you need a robust training management system to ensure you can do so.

Training puts everyone in your company on the same page, ensuring that Part 210's definitions are understood and applied in a uniform way.

Ensuring adequate facility, equipment and control systems

21 CFR 210 doesn't specifically mandate facility, equipment and control requirements - those come in Part 211.

But where your cGMP activity happens is crucial, and the defined terms in Part 210 give a hint of the scope of operations that your business needs to structure and maintain.

A physically clean and well-organized manufacturing facility with full control of lot and batch distribution, product sampling, component onboarding and so on, is the cornerstone of your Part 210 compliance and the baseline where the more specific requirements of Part 211 can be brought to life.

Need some extra help? Read our list of the 5 best pharmaceutical consultants in 2023

Stay up-to-date with 21 CFR Part 210

21 CFR Part 210 guidelines for pharmaceuticals are just one of a series of interacting elements defining modern cGMP.

And the 'c' is vital here: the boundaries of good manufacturing practice are increasingly and constantly being shrunk as regulators raise the bar of expectations.

Although 21 CFR 210 in itself hasn't changed for many years, it's still important that your organization remains constantly attentive and abreast of what cGMP means for you.

At the same time, you should consider the tools, techniques and processes your business adopts as you look to embed Part 210/211 compliance.

Legacy tools like paper and spreadsheets clutter and complicate your compliance, making it more difficult to pinpoint and fix process errors and diverting your valuable time into non-value-add admin.

Alongside modern cGMP technology like digital manufacturing lines and distributed control systems, electronic quality management systems infuse cGMP into your company culture by connecting teams to a centralized source of truth for documentation, training, quality events and more.

Implications of non-compliance

Since 21 CFR 210 compliance is mandatory, failure to embed its requirements could result in a warning letter, import alert or a Form 483.

Persistent non-compliance could result in the permanent shutdown of your organization.

FURTHER READING:

5 notorious compliance issues in the pharmaceutical industry

Resources for staying compliant

Download our GxP toolkit for a range of helpful cGMP resources, tips and insights.

And take the first step to natural, automatic and digitized cGMP and 21 CFR 210 compliance by booking a demo of our eQMS software!