Mastering quality management in laboratory environments: 12 essential techniques for 2026

Nowhere is quality management more crucial than in a laboratory environment. A tiny error like mixing up a specimen or wrongly identifying a patient can bring potentially catastrophic results.

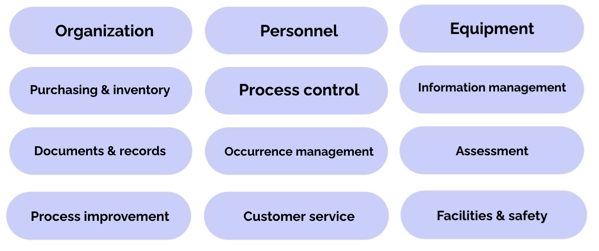

The quality management requirements for laboratories in life sciences are extensive and touch on everything from equipment to customer service.

With a firm understanding of the 12 essential ingredients of quality management in laboratory environments, you'll be able to confidently drive your lab quality control to new levels of excellence in 2026 and avoid potentially life-threatening mistakes.

Table of Contents

What is quality management in laboratory environments?

Laboratory quality management, actioned through the laboratory quality management system (QMS), is the bundle of processes, activities and information that guarantee the integrity of the work done in your laboratory.

It's simple: the stronger and more connected your laboratory quality control, the greater the quality, efficiency, speed and safety of your laboratory work - and its outputs.

Quality management in laboratory environments: the 12 essentials

In a laboratory, it’s essential to follow and maintain stringent laboratory quality control and quality management process.

If not, your laboratory risks losing its accreditation from regulatory bodies. Quality control in a laboratory should therefore touch all aspects of your processes and procedures, with robust laboratory quality control acting as the core of your operation.

The model for the following 12 essentials comes from the Clinical and Laboratory Standards Institute (CLSI), as well as ISO 15189.

Life science professionals take these 12 tenets of laboratory quality control very seriously, because the cost of quality issues is so high.

“Not fully implementing the 12 essentials of quality could lead to issues... such as treatment complications or unnecessary treatment, delayed diagnosis, poor patient outcomes, increased cost in time and work, and unnecessary follow-up diagnostic testing,”

- Tom Zafred, Biomed Systems

1. Organization

Your laboratory quality control needs to be organized around a formal quality management system that supports consistent procedures. The management team and quality unit play an integral role in a laboratory quality control-focused culture, along with structures for monitoring ongoing quality control in the laboratory.

2. Personnel

Capable, qualified staff members are the single most important asset to quality control in a laboratory. Training, motivation, and engagement are key parts of the quality management system. You also need to document all of your training processes within your quality management system.

3. Equipment

Every piece of equipment used in the laboratory must be maintained to operate safely. Also, laboratories need to monitor how equipment is installed, which suppliers provide the equipment, any calibration processes, and when the equipment needs to be replaced to maintain the highest possible quality.

4. Purchasing and inventory

Properly managing the supply chain is critical to ensure that raw inputs and other supplies are consistently high-quality. Inventory activities should verify that materials and supplies are stored in a way that protects integrity. Make sure you purchase inventory from suppliers who also follow a quality management system - your own lab quality control rests on the strength of who you do business with!

5. Process control

Process control encompasses laboratory quality control processes for testing, including:

- Collection

- Handling

- Method verification

- Process validation

If you're struggling with process control, design control software can dramatically improve internal efficiencies. Within the software, you can document all processes related to each step of lab quality control, such as the testing required for verification and validation or internal audits.

6. Information management

The laboratory produces many forms of information, including lab quality control test results, maintenance reports, and other data. Along with that, the lab processes patient information such as medical exams, results, and more. This data needs to be managed in a way that ensures all information is accurate, secure, confidential, and accessible to individuals with the right privileges, such as lab managers and leadership.

7. Documents & records

Documents are a similar concept to information management, and there’s a significant overlap between these categories. One of the most essential groups of laboratory quality control documents is the standard operating procedure (SOP) that creates a standard for each process. Documents need to be available at the point of work, maintained, accurate, and secure. Finding the right document management software should be a mission-critical focus for any growth-oriented life sciences company.

8. Occurrence management

An “occurrence” is any error or non-conformance. eQMS software can help you detect these issues and facilitate investigations to discover the root cause and prevent reoccurrence. A laboratory QMS can also assist you if you’re going through an audit, as it’s much easier to document these occurrences and what you did to fix them.

9. Assessment

Assessment involves comparing laboratory performance to internal standards for quality or external data sets, such as industry benchmarks. Laboratory quality control assessments include the activities of lab or QC managers, internal auditors, or external inspectors.

10. Process improvement

A quality management system should support the continuous improvement of laboratory processes, and quality control in a laboratory. Components of the QMS which support improvement can include quality assurance, lab quality control, and CAPA (occurrence management). We recommend investing in training management software to build and activate major improvements to internal processes.

RELATED READING: 12 questions to ask before buying an eQMS

11. Customer service

Customer service is the ultimate goal of a laboratory. A laboratory’s QMS should support operations that consistently provide a positive customer experience through the production of consistently high-quality products or other missions. The laboratory needs to understand the customers and their needs and use customer feedback for improvement.

12. Facilities & safety

Laboratories need a comprehensive set of procedures and standards to ensure a safe, secure, and clean environment with robust lab quality control. This includes physically securing the lab, containment procedures for hazards, worker safety, and ergonomics.

The role of software in laboratory quality management

ISO and the CLSI don’t specify exactly how quality control in a laboratory should happen. They simply define a quality management system as “coordinated activities to direct and control an organization with regard to quality.” But in practice, achieving the 12 essentials of quality requires purpose-built software.

A laboratory quality management system needs all 12 of the essentials to support consistently high-quality operations, and systems to ensure these elements are working in sync. If your QMS is missing several elements, such as document control or physical security, the entire system can easily crumble. Similarly, if your laboratory quality control hits all the basics but you can’t coordinate between the essentials by understanding the bigger picture of quality trends or root causes, you’re at risk of non-conformance and recurring issues.

Software isn’t strictly required by ISO standards or regulatory agencies, but it makes robust, repeatable lab quality control much simpler. The right software can help you avoid having to reinvent the wheel by building a QMS from the ground up. Trying to coordinate lab quality control processes with paper systems can lead to poor visibility and human error, and clutter and complicate your laboratory quality control processes.

Qualio is the first cloud-based QMS for life science laboratories, built specifically in accordance with ISO and FDA best practices. It includes all the essentials to help fast-growing lab start-ups and scale-ups create a solid quality baseline. Learn more here!